Solar Panel Innovation Using “Optical Tracking” Technology Increases Energy Harvesting Up To 30 Percent

Lake Mary, FL., May 31, 2012, Advanced Solar Photonics, LLC (ASP), an American manufacturer of photovoltaic equipment and provider of turnkey alternative energy systems, today announced it is introducing the first mono-crystalline bifacial glass-to-glass PV module series made in America.

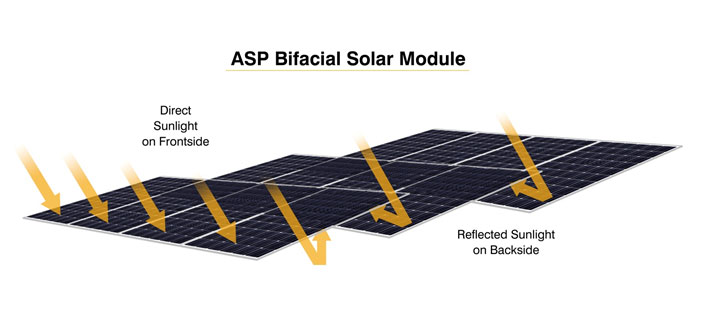

The bifacial dual sided glass module (G2G) generates more electricity by converting direct, radiant and scattered solar energy on both the front and the back side of the module. The thinner tempered glass means the light does not travel as far, increasing overall module efficiency by 10%. To further increase the efficiency, ASP uses a special holographic material sandwiched between the silicon and EVA layers, maximizing the time per day the modules can generate electricity from the sun. ASP bifacial G2G modules also have a low temperature coefficient, which allows them to produce more electricity than conventional crystalline silicon solar modules at the same temperature. Together these features can result in energy output as much as 30% higher than conventional technology.

“The bifacial G2G technology marks a major turning point in photovoltaic system technology,” said Thomas Gregory, Chief Strategy Officer at ASP. “We’ve replaced costly single-axis and double-axis mechanical tracking systems with much cheaper optical tracking panels and achieved the same efficiency increases.”

Assuming an average system cost of $4/Watt for a conventional fixed ground-mount system, a double-axis tracking system would add about $1/Watt to the installed cost of the system and increase energy generation by approximately 30%. ASP’s bifacial G2G panels will also increase energy generation by about 30% but only add approximately $0.50/Watt to the overall cost of the system. In other words a 12.5% increase in cost will add 30% in energy revenue for system owners.

The glass-to-glass lamination method, with no multi-layer back sheet, results in reduced fire hazard and less probability of mechanical damage over the lifetime of the module. The G2G architecture provides dual sided protection of silicon materials from extreme weather conditions. Thinner glass ensures less heat, thermal stability, resistance to impact and elimination of micro fractures. A frameless construction requires less connections, materials and labor resulting in compact packaging and facilitated transportation. The bifacial G2G modules have a usable lifetime of 50 years without danger of mechanical damage or temperature/ humidity-related delamination of the back sheet, resulting in a loss of energy production performance or outright failure.

This breakthrough PV product is made up of 60 bifacial mono-crystalline silicon cells with up to 20.5% module efficiency on both sides. The total rated power output of the panel will range from 271 Watts to 333 Watts. Bifacial modules are ideally suited for applications with limited ground space such as military bases, municipalities, and schools. In addition, modern rooftop designs using reflective materials for cooling would maximize the harvesting from that enhanced reflectivity.

ASP will be featuring the new bifacial G2G product along with the ASP 400 Watt series of PV modules in their booth on the first level at Intersolar North America on July 10-13, 2012 in San Francisco, CA.

###

Advanced Solar Photonics, LLC (ASP), is a manufacturing and R&D center for crystalline silicon solar photovoltaic (PV) panels for utility, commercial and residential applications. Based on the latest cell efficiency, light transmission, and encapsulation technologies, ASP focuses on high-efficiency, state-of-the-art solar PV modules ranging from 200 Watts to 400 Watts. ASP is the second largest producer of crystalline silicon PV panels in the United States and is one of the few producers in the US of Buy American Act compliant products suitable for government, military and municipal projects.